Equipment spotlight: The Heidelberg(s)

You may not know it, but I’m a talker. And not the tell you every detail about my day kind of talker, but the talk to whatever inanimate object might be listening kind of talker. And it often feels like a two-way conversation.

That especially goes for my printing presses, the platen press Heidelbergs. Notorious for their printing chops around the studio, these handsome workhorses are otherwise known (by me) as Harold and Big Hal, and they have a story of their own to tell.

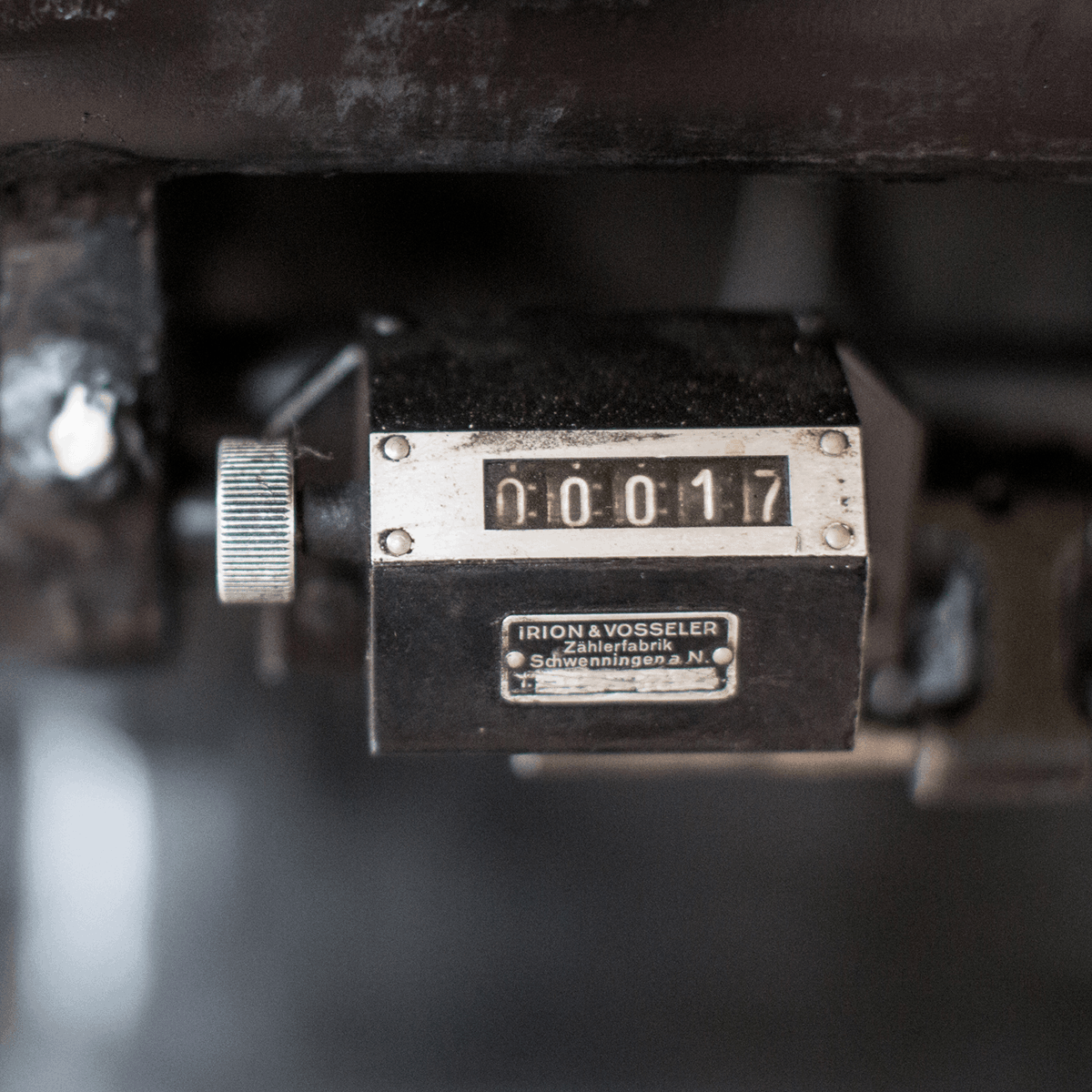

Year built: 1951

Model: GT 13×18

Serial number: 52 693 E

Dimensions: 4’10” wide and 6’10” deep

Made in Germany

Year built: 1968

Model: Tiegel 10×15, Red Ball

Serial number: T 169 462 E

Dimensions: 4’1 wide and 5’6″ deep

Made in the U.S.

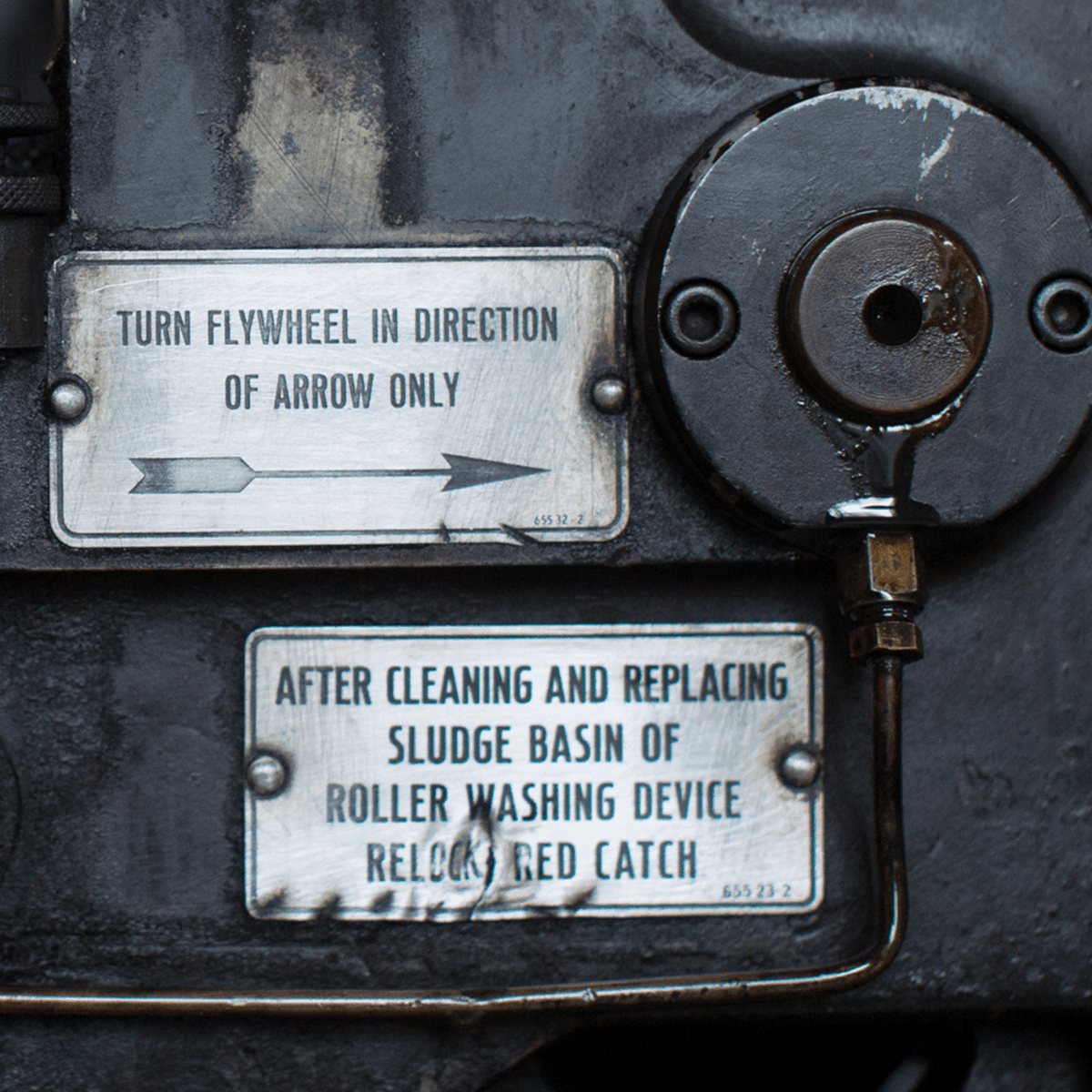

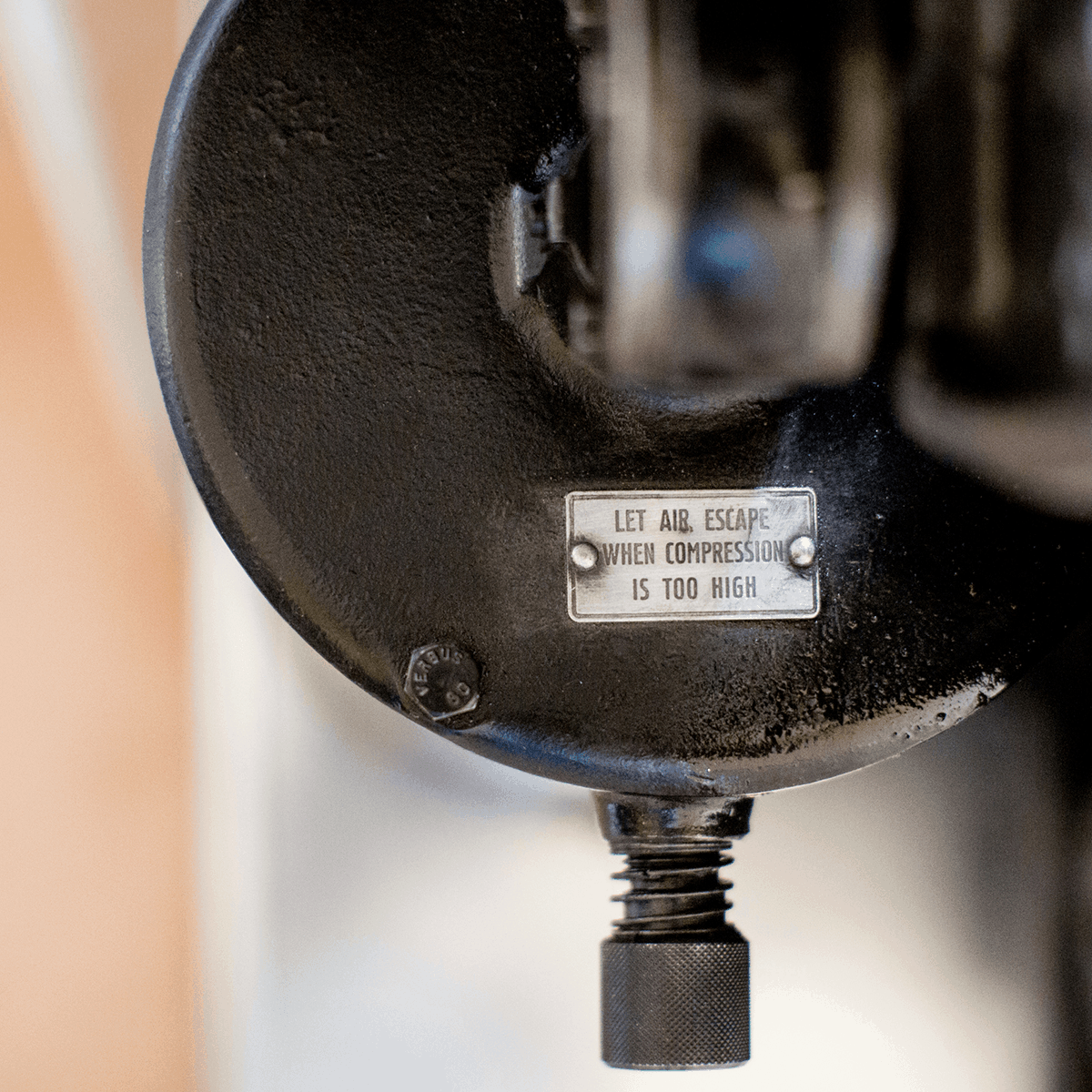

That’s what happens when you’ve been around the block – or the printing blocks for fifty years. My handsome fellas have a different perspective, a rhythm and fortitude unimpeded by the passage of time. Through their measured breathing and recurrent sounds, I find a peace and quiet confidence that I sometimes use as my creative guide.

At their youngest, they could imprint more than 5,500 and 4,000 pages an hour. Now, at a young 48 and a slightly more mature 65, Harold and Big Hal haven’t slowed down. As old as they are, I am challenged to keep up when they’re barely pushing their minimal speed.

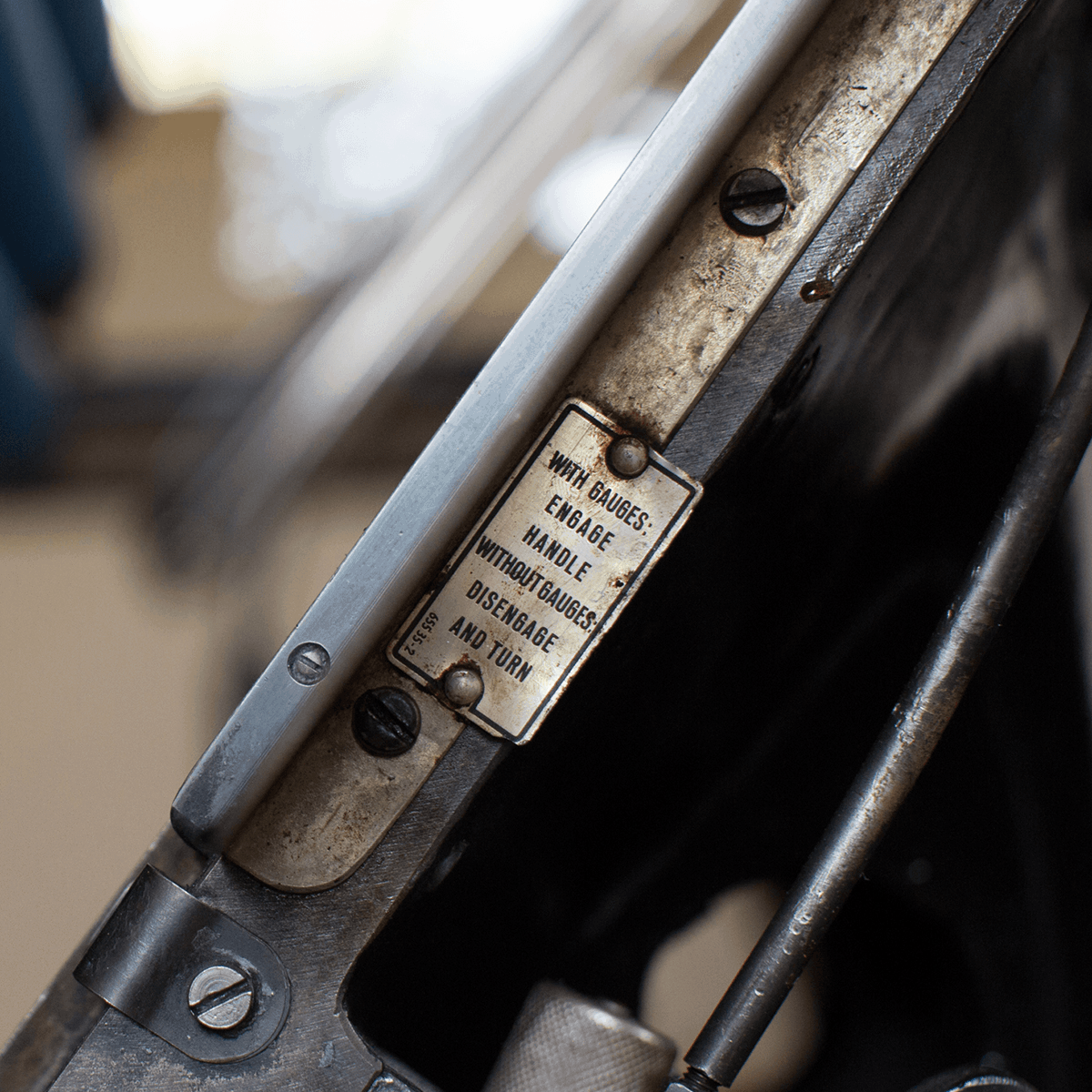

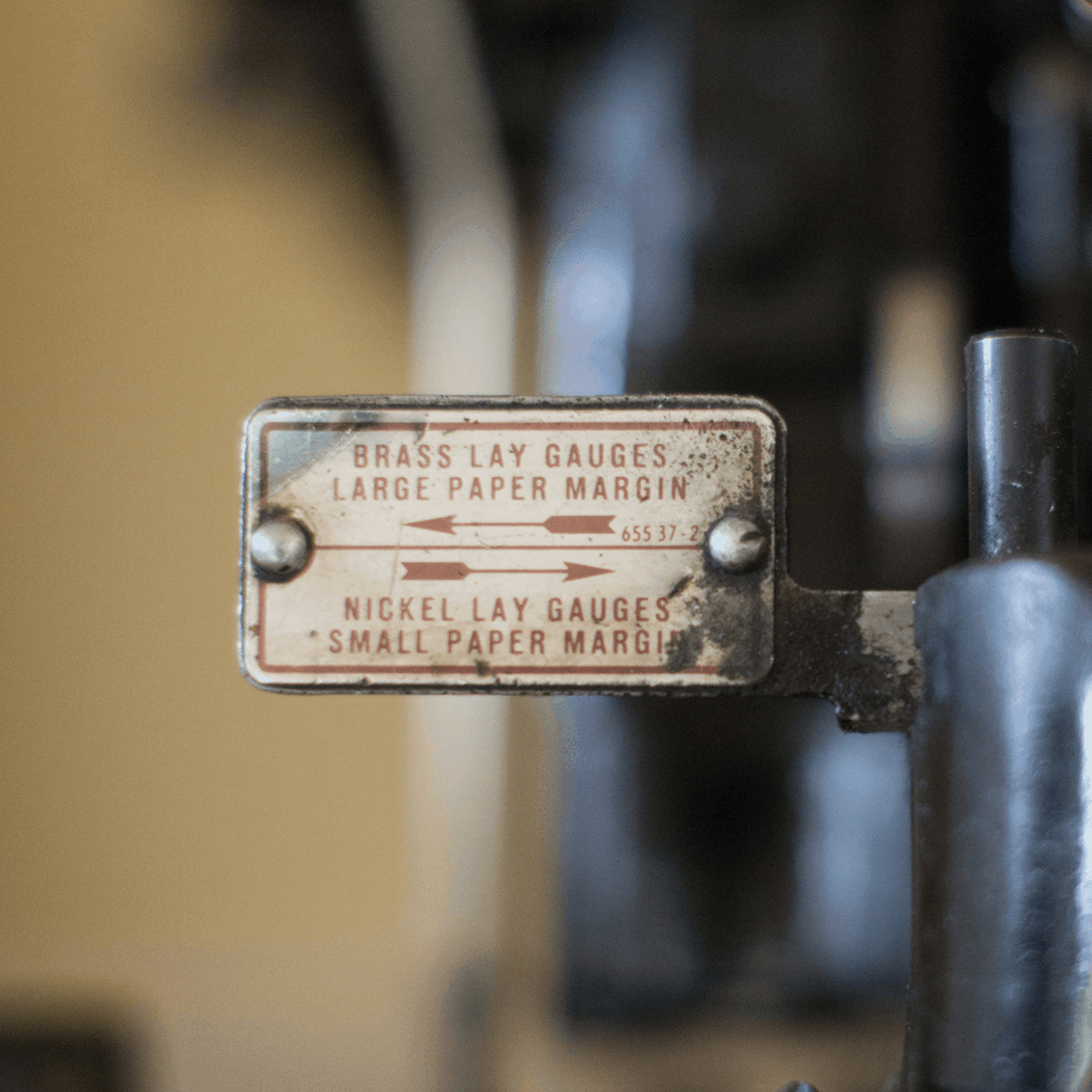

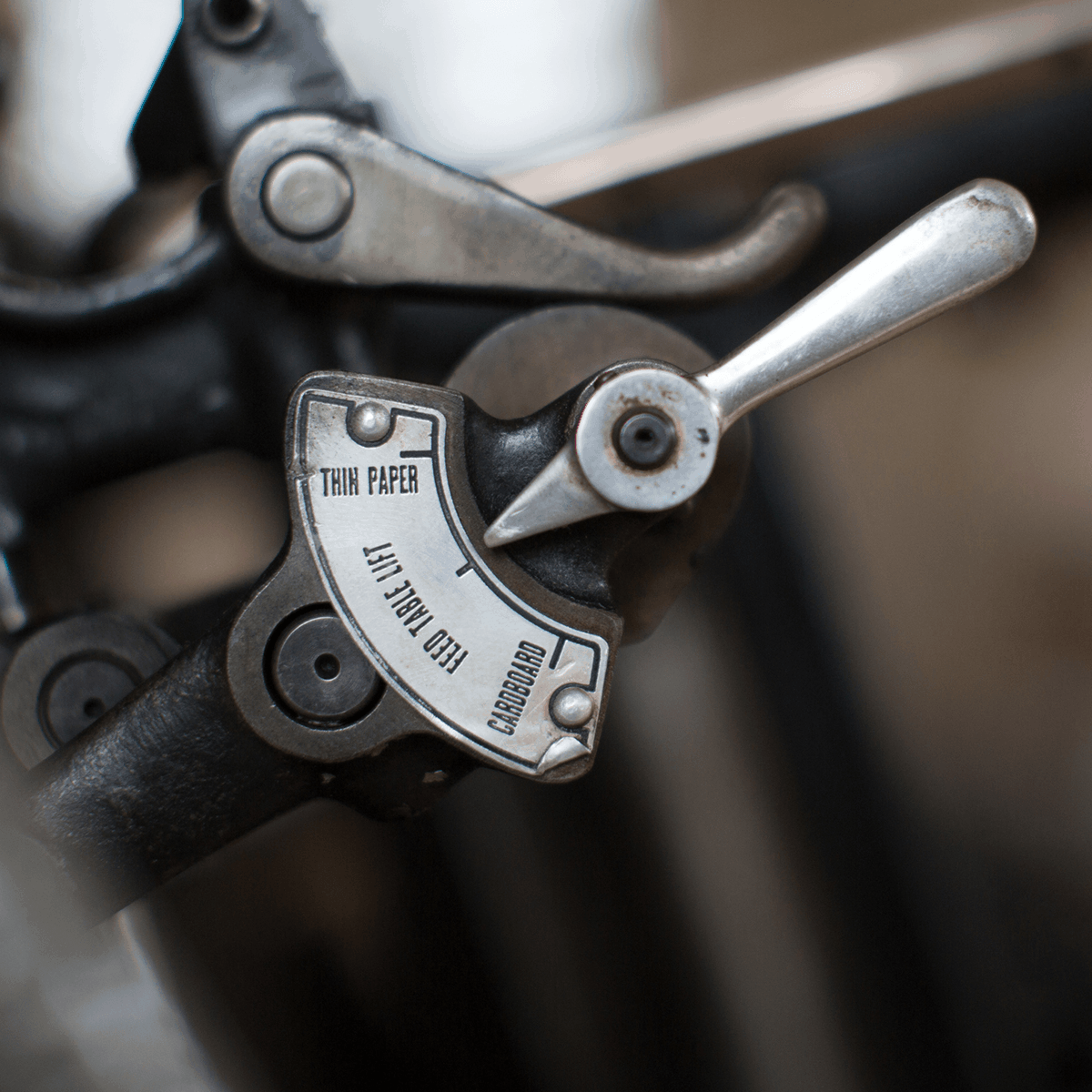

Even at their fastest (or my fastest), they never skimp on quality. I love these fast talkers for their unrivaled production quality that has withstood the passage of time. Whether printing on tiny or large pieces of paper, the Heidelbergs leave a strong and even impression – inking consistently and letting me confidently control the flow of ink.

They perform to exacting standards without a hiccup or grumble. I can count on Harold to print on paper as small as 1 1/2” x 2 3/4” and Big Hal can go as big as 13 3/8” x 18 1/8”. AND they can handle ranges of paper size and strength while weighing in at 2,300 and 4,950 pounds respectively. To be so delicate with such a hulking physique?

They’re my dream team. The strong and silent types that hear me out and reply with their own unique voice – some times with the quick clicks of a job in progress, other times the sigh of a job well done.

Always, though, there’s a connection. The connection and conversation I have with these magnificent machines and the work we can do together.